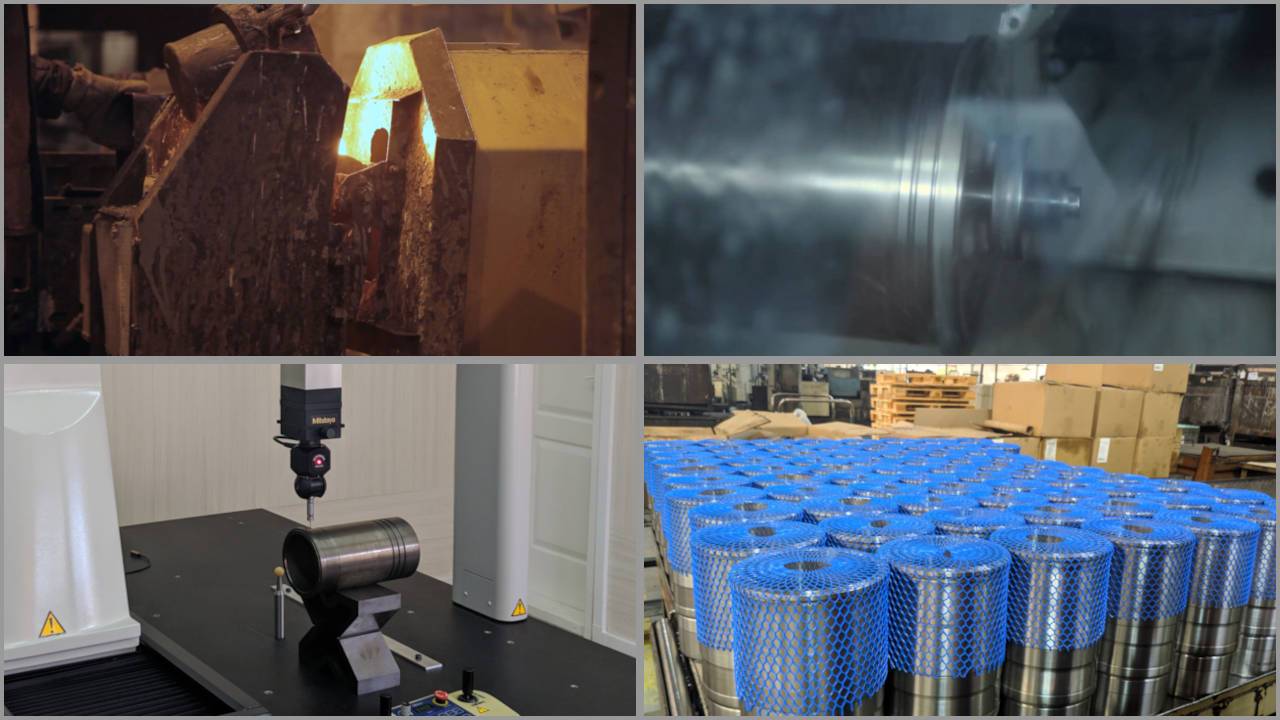

Повний цикл виробництва наступної продукції:

Гільзи циліндрів для легкових автомобілів.

Гільзи циліндрів для вантажних автомобілів.

Гільзи циліндрів для сільськогосподарської та спеціальної техніки.

Втулки циліндрів для теплотяжних, суднових та промислових двигунів.

Втулки циліндрів для ремонту компресорів.

гільз на рік

найменувань гільз циліндрів

співробітників

тонн придатного литва на рік

країн, до яких експортується продукція

кв. м виробничих площ

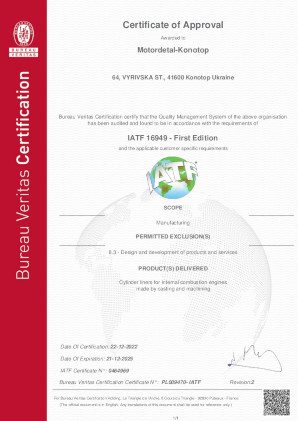

Сертифікати які підтверджують якість нашої продукції.